Metal powders

METAL POWDERS

VMP GPOUP manufactures fine and superfine zinc, copper and bronze powders and powder mixture for thermodiffusion zinc coating (Sherardizing).

VMP HOLDING technologies of metal powder production are protected by the patents and have many advantages such as easy process control, easy transition from one product type to another, efficient production, low transaction costs, environmental safety, and constant high quality.

The quality management system is certified by ISO 9001:2000.

Recommended use:

- in coatings;

- for Sherardizing;

- for gas-thermal, gas-dynamic и other methods of sputtering;

- as catalysts in chemical processes; reagents in chemical industry;

- as components of solder, pasts for electronic and electrical industry;

- as components of antifriction or antiwear additives and others.

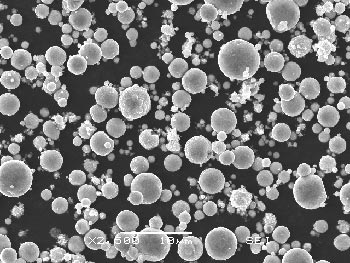

ZINC DUST

ZINC DUST COPPER SUPERFINE POWDER

COPPER SUPERFINE POWDER BRONZE SUPERFINE POWDER

BRONZE SUPERFINE POWDER POWDER MIXURE for thermodiffusion zinc coating

POWDER MIXURE for thermodiffusion zinc coatingPZVD-0

Zinc Dust

(ТU 1721-002-12288779-2006)

Technical data:

| Properties | Typical Value | |

| Appearance | Fine grey powder | |

| Particle shape | Spherical | |

| Chemical composition, % (Wt) | ||

| Metallic Zinc | 96.0, not less | |

| Impurities | Fe | 0.005, not more |

| Pb | 0.013, not more | |

| Cd | 0.004, not more | |

| Cu | 0.001, not more | |

| Sn | 0.001, not more | |

| As | 0.0005, not more | |

| Matter insoluble in diluted hydrochloric acid (1:1) | 0.05, not more | |

| Particle size distribution, % (Wt) | ||

| > 20 microns | 15, not more | |

| 12 – 20 microns | 30, not more | |

| 4 - 12 microns | 50, not more | |

| < 4 microns | 25, not more | |

| Apparent density, g/ml | 1.7-2.5 | |

It is packaged byТУ 1721-002-12288779-2006.

Shipping weight is 25 kg in metal cans.

State Registration Certificate No. 66.01.10.172.П.000525.02.06 /17 February, 2006.

Recommended to use:

- for gold extraction by alkaline leaching methods in metallurgy;

- as a catalyst;

- in protective coatings applied by Sherardizing, gas-plasma and other sputtering methods on metal structures;

- in metal cladding lubricants.

PMVD

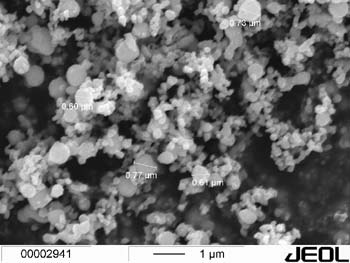

Copper superfine and ultrafine powders

ТU 1790 – 040 – 12288779 – 2005

Technical data:

| Properties | Typical Value | |

| PMVD - 0 | PMVD - 1 | |

| Appearance | From light to dark brown fine powder | |

| Total copper*, %, not less | 99,96 | 99,90 |

| Oxygen matter content, % (Wt), not less | - | - |

| Fraction content, % (Wt):

- < 3 microns - > 3 microns - 3 – 20 microns - > 20 microns |

50, not more - 45, not more 5, not more |

30, not more - 65, not more 5, not more |

| Apparent density, g/ml | 0,10 - 1,00 | |

| Specific surface area, m2/g | 2,0 - 10,0 | |

*difference between 100 % and sum of impurities (Ag, Al, As, Au, B, Ba, Be, Bi, Ca, Cd, Co, Cr, Fe, Ga, Hg, In, K, Li, Mg, Mn, Mo, Na, Nb, Ni, P, Pb, Re, S, Sb, Se, Si, Sn, Sr, Te, Ti, Tl, V, W, Zn, Zr).

It is packaged by ТУ 1790 – 040 – 12288779 - 2005

Shipping weight is 10 kg in metal cans.

State Registration Certificate No. 66.01.10.179.П.002200.10.05 / 24 October, 2005.

Recommended to use:

- in electronic, electrical, precision engineering, automobile, aircraft, chemical industries;

- for coatings, construction materials and

- for metal structures, coatings, construction materials, and others.

PBVD

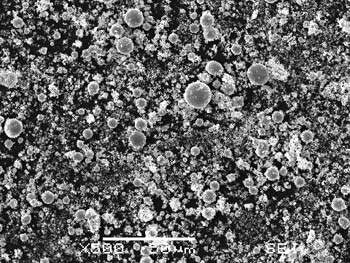

Bronze superfine powder

ТU 1790 - 007 - 12288779 – 2006

Technical data:

| Properties | Typical Value | |

| PBVD-1 | PBVD-С | |

| Appearance | Dark reddish-brawn fine powder | |

| Particle shape | Spherical | |

| Chemical composition, % (Wt) | ||

| Cu | 89,0-98,0 | 86,0-94,0 |

| Sn | 1,0-10,0 | 2,0-6,0 |

| Sb | - | 3,0-7,0 |

| Hydrogen loss, % (Wt) | 1,0 | 1,0 |

| Fraction content, % (Wt) > 20 microns | 5,0 | |

| Apparent density, g/ml | 0,3 – 1,2 | |

| Specific surface area, m2/g | 2,0-8,0 | |

It is packaged by ТУ 1790-007-12288779-2006.

Shipping weight is 10 kg in metal cans.

State Registration Certificate No. 66.01.40.179.П.000761.03.08 / 06 March, 2008.

Recommended to use:

- in antifriction or antiwear compositions, superconcentrates (masterbatch) for plastics, fitting pastes;

- in bearing production,in diamond tool and ceramics.

POWDER MIXTURE for thermodiffusion zinc coatings TEDIZIN

ТU 721 - 024 - 12288779 - 2006

POWDER MIXTURE for thermodiffusion zinc coatings TEDIZIN is designed for zinc coating (Sherardizing) to protect fastening and other goods from carbon and low-carbon steel, and cast iron.

POWDER MIXTURE consists of:

- component А – a inert filler packaged in polypropylene bags; shipping weight is 50 kg;

- component В – a zinc powder packaged metal cans; shipping weight is 25 kg;

- component С – a activating composition packaged metal cans; shipping weight is 15 kg.

State Registration Certificate No. 66.01.40.172.П.004365.12.02 / 27 December, 2007.

Component А is an inert refractory material applied in 10 - 15 production cycles (depending on surface preparation of goods) after coating quality decreases it should be utilized with no restrictions. Component В (zinc powder) and component С (activator) are additives in every production cycle and their quantity depends on surface square and dry film thickness, they have been used completely during one cycle.

The quantity of component B per goods quantity деталей is calculated by the equation:

mZn –quantity of component B (zinc powder) (g);

F – specific surface area of goods (m2/g);

m – goods quantity (kg);

d – dry thermodeffusion film thickness (micron).

If a specific surface area of goods is unknown that quantity of component B is taken to be 0.4-0.8 g per 1 kg of goods to get 1 micron film thickness, then quantity of component B is corrected depending on achieved film thickness. At the average, to achieve 1 micron film thickness on 1 m2 area it is necessary to use 7 g of the component В.

Component С is loaded as 10- 20 % by weight of component В.