Application

How to choose a protective coating

Due to a wide variety of paints and varnishes it is often quite difficult to independently choose a complex coating that will meet all the requirements and provide the necessary level of protection of structures against corrosion

Basic criteria for the right choice of protective coating

Protected surface type:

-

Steel structures

- Concrete and reinforced concrete structures

Surface preparation:

- Abrasive blasting

- Manual or mechanical tool

Environmental corrosivity category:

ISO 12944 STANDARD

Atmosphere

- C1 - very low

- C2 - low

- C3 - medium

- C4 - high

- C5-I - very high (industrial)

- C5-M - very high (marine)

- Im1 - fresh water

- Im2 - sea water

- Im3 - soil

SNIP (Construction Norms & Regulations) 2.03.11-85

- Non aggressive

- Slightly aggressive

- Moderately aggressive

- Very aggressive

Based on the products manufactured, the VMP specialists developed coating systems for media with varying degrees of corrosion activity.

Required coating service life:

- Low - from 2 till 5 years

- Medium - from 5 till 15 years

- High - over 15 years

VMP Holding specializes in the development of coatings with high and medium service life

Conditions for applying a corrosion-resistant coating:

- Winter season

- Summer season

- Factory

- Construction site

VMP range includes

VMP coating materials are formulated for

painting works and application of materials both at the factory-manufacturer of metal structures, and directly at the installation site, as well as in various climatic conditions

When choosing a coating system, you can refer to the current industry regulatory documents, enterprise standards and state standards.

The list of documents can be found in the section Certification.

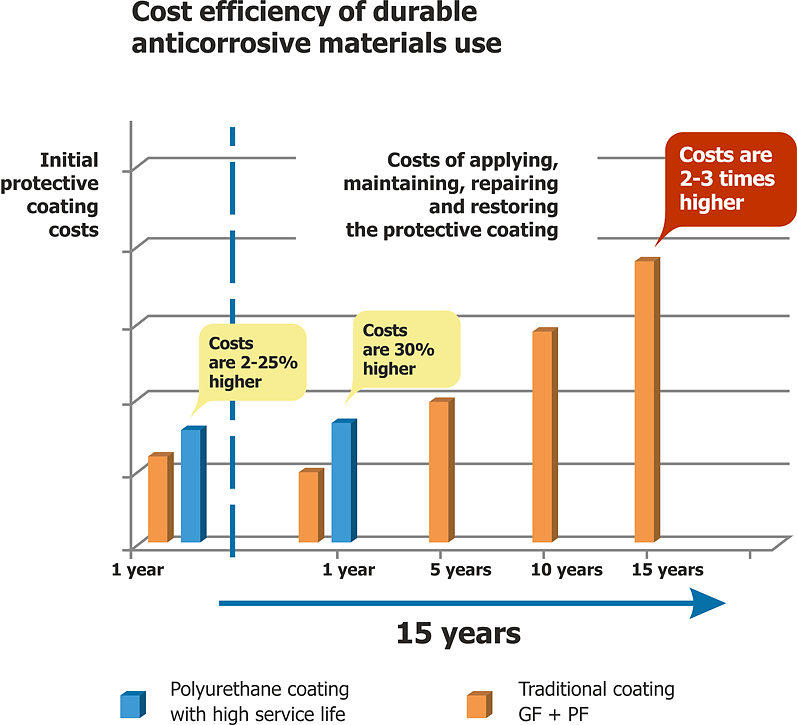

Cost efficiency

VMP can offer coating options with medium service life based on materials from the “middle” price segment.

It should be taken into account that one-time savings on the initial cost of creating a protective coating entails significant costs for further repair of the coating.

During 15 years of operation of the facility

The total cost of creating and operating a coating of traditional materials is 2-3 times higher than the cost.

The increase in the cost of operating coatings is associated with the need for periodic restoration. It is necessary to take into account the increase in costs for the annual inflation rate, the remoteness of the location of oil and gas facilities, while the economic efficiency of using durable coating systems will increase significantly.

- Oil and gas industry

- Chemical industry

- Power industry

- Metallurgical industry

- Transport construction

- Hydraulic engineering

- Ship building and ship repair

- Civil engineering

Our specialists can provide assistance

for you in choosing coating systems